CATALOG

Pipe Support Stands

Pipe support stands should always be used when rolling or cutting grooves in pipe. For cut grooving they are essential to keep the pipe level; for roll grooving, stands are adjusted to provide the slight downward pitch needed to keep the end of the pipe in firm contact with the back flange of the bottom roller. In every size range, Pace stands are made extra-rigid to prevent the "pendulum effect" which-with less sturdy stands-can whip the pipe off the sup¬port stand during a roll grooving operation.

Model 4000 - PIPE SUPPORT STAND

Specifications: Capacity: 2" through 8" Pipe; 900 lbs. max.

The base of this stand is the same as used in Model 4031, above. A saddle with four roller bearings provides greater side support for the pipe and increased dampening of vibration without impairing the unit's free-rolling characteristics. Saddle height is adjustable over a 10" (254mm) range.

The four-roller-bearing saddle may be ordered alone as No. 4001. Replacement roller bearing is No. 4025.

Model 4031 - PIPE SUPPORT STAND

Specifications: Capacity: 1" through 4" Pipe; 600 lbs. max.

A 22" diameter base and 2" column give this stand plenty of strength for supporting any pipe in its size range. The saddle has two roller bearings for free rotation of the pipe, and absorbs vibration to ensure a smooth, uniform groove. Saddle height is adjustable over a 10" (254mm) range.

The two-roller-bearing saddle may be ordered alone as No.4032. Replacement roller bearing is No. 4025.

Model 4033 - PIPE SUPPORT STAND

Specifications: Capacity: 2" through 14" Pipe; 1200 lbs. max.

This extra-heavy-duty pipe support stand uses two 2" columns on a 22" diameter base to give it exceptional stability and resistance to vibration and pendulum effect. Each column incorporates a sturdy, threaded post infinitely adjustable over a 10" (254 mm) range. The saddle utilizes six roller bearings in an array that provides excellent support for all pipes in its size range. Replacement roller bearing is No. 4025.

Model 4040 - PIPE SUPPORT STAND

Specifications: Capacity: 12"-24" Pipe; 4000 lbs. max.

This is our SuperStand! Fabricated of 6" diameter steel pipe welded to a 36" diameter base, this massive stand can support up to two tons of pipe during grooving operations. Pipe saddle height is adjustable over a 5" (127 mm) range.

Porta-Bore

Model 3013 - PORTA-BORE

Specifications: Heavy-Duty -- 42 lbs, 110, 175, 245, 385 RPM. Cuts up to 4 1/2" diameter holes in 1 1/4" through 12" diameter pipe. 110 volts 10 amps, (220 Volts is available).

Designed for fast and efficient operation, using Slugger(R) cutters, hole saws, and drills. Solid alloy aluminum construction. It is the most ruggedly constructed machine in the industry. Slide and gibbs are heat-treated aluminum with a Teflon coating to ensure long life. Slide assembly is positioned together by gauge block machining. This assembly is located by dowelled gibbs that are aligned precisely with the V-block. There are no elongated holes, which could allow for misalignment. Motor, 10-Amp Draw Industrial Drill Motor with Internal 4-Speed Gear Box 110, 175, 245, 385 RPM Spindle, No. 3 Morse Taper Electrical Panel Meets the Highest Standard for Safe Operations. Circuit Breaker Ensures No Safety Hazard to the Operator or Machine Arbor Support Design for Ease with Slugger(R) Cutters or Drill Chuck for Use with Hole Saws or Drills Chain clamp Standard on All Units and Clamps to Pipe Diameters 1 1/4" through 12"* *OPTIONAL: Speed Toggle Clamp, Clamps 1 1/4" through 6" Pipe. Both lamps ensure positive holding during hole- cutting operations and can be used in any position. Easy Part Replacement: Building Block Design Allows Easy Part Repair or Replacement. (No need to ship machine out for repair).

Pipe-Cut Groover

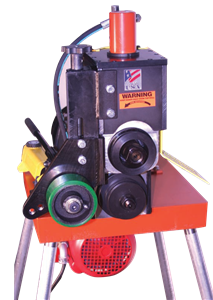

Model 1000 - PORTABLE CUT GROOVER

Specifications: Capacity: 2" through 12" Schedule 40 (10mm) 2 1/2" through 8" Schedule 80 (13mm) Power: 1 hp, 115-230V.

Cuts grooves in 2, 2 1/2", 3, 3 1/2", 4, 5, 6 and 8" Schedule 40 pipe. Collet Chucks for 10" and 12" Pipe Available Tooling for Cut Grooving Ductile Iron Pipe also Available Special Collet Chucks for Non-Standard Dimension Pipe Can Be Supplied The PACE Model 1000 is complete with 8 Collet Chucks, 4 High-Speed Steel Grooving Blades, and a Groove Gauge and is delivered ready to cut specification- quality grooves in the complete 2" through 8" range of Schedule 40 pipe. Quick setups for each pipe size and simple operation make the PACE Model 1000 an extremely cost-effective tool for the fire protection and mechanical contractor. A 1-hp motor, driving through a heavy-duty worm gear reducer, rotates pipe at 22 rpm for most effective cut grooving. Model 1000 is moved easily to the jobsite because it weighs only 185 lbs. Enclosed Single-Phase Motor. Capacitor Start. Output Speed 22 RPM. Working Height: 38" Weight: 185 lbs. The PACE Pipe Cut Groover is shipped in a sturdy wooden box with storage area for individual collets, gauges, and blades.

Buck-on Machine

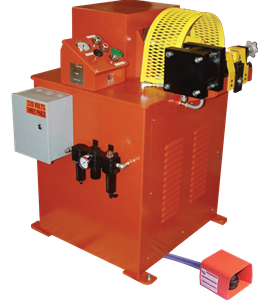

Model 8100 - Buck-on Machine

Specifications: Height: 43" Width: 34" Depth: 34" Motor: 3 HP, 3 phase, 220V Weight: 650 lbs

Fast, Accurate Fitting, Installation on 1", 1 1/4", 1 1/2" and 2" Pipe. Infinite Torque Adjustment Range Easy to Operate Engineered for Production Work No Bushing Boxes Required The PACE Buck-on Machine helps you improve productivity by bucking-on a wide variety of fittings quickly and accurately. It reduces the time you spend waiting for pipe and fittings to be joined. And that improves profitability. PACE has streamlined the buck-on process with a new clutch design and universal cam chuck. The new clutch allows an infinite range of adjustment for better results with any type of pipe dope. The simpler clutch design also means greater reliability, eliminating costly downtime. In addition, the universal cam chuck saves setup time by eliminating the need for keys and box liners. EASY TO OPERATE To use the PACE Buck-on Machine, you simply turn the knob until the indicator needle matches the prescribed pressure setting. Then place the fitting into the jaws, adjust the size with a hex key, slide the pipe in place, and use the foo switch to clamp the pipe. The air system will clamp the pipe with the proper pressure automatically. It also assures safety by locking out the start cycle unless the pipe jaws are clamped. BUILT FOR PRODUCTION WORK Pace has engineered the Buck-on Machine to stand up to the rigors of all-day, everyday use. Its electronic motor, cooling fan, and filters are housed on a sturdy steel cabinet. STANDARD EQUIPMENT Guard comes ready to run, as shown in the picture. OPTIONAL: 1/2"–3/4" Pipe inserts, Box Jaws

Accessories

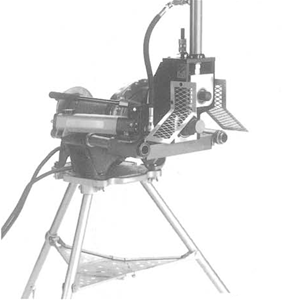

Model 1041 - PIPE ROLL GROOVER ATTACHMENT FOR USE WITH RIDGID® 300 PIPE THREADER

Specifications: Capacity: 1" through 8" Schedule 40 (6mm) 1" through 12" Schedule10 (5mm) 2" through 8" Copper Tubing K, L, M, and DWV Maximum Pressure at Roller: 8,000 psi

Quickly converts your RIDGID(R) 300 Threaded to a production roll groove Mounts/Dismounts Easily on Standard Model 300 Capacity: 1" through 12" Pipe (25-305mm). Shipping Weight: 94 lbs. (42.6 kg) Interchangeable Rollers: TOP PIPE DIAMETER/BOTTOM PIPE DIAMETER 1" through 6" (25-152 mm)/ 1" through 1 1/2" (25-38mm) 8" through 12" (203-305mm)/ 2" through 6" (51-152mm)

Model 4037 - NIPPLE BRACKET

Specifications: Capacity: 8" through 24" (203-610mm) Pipe. Fits Models 1020, 1021, 1023, 2020, 2021, and 2050 Roll Groovers

This nipple bracket was developed to permit safer, more efficient roll grooving of pipe too short to mount in a pipe stand. The plastic composition clamp-roller fixes pipe nipple in a controlled, slightly eccentric position so that the pipe is held firmly against the back flange of the bottom roller as it rotates. Pipe nipples as short as 6" can be grooved using this tool, permitting high production rates without the need for manual positioning by shop personnel.

Model 4039 - MOUNTING FEET

Specifications: Fits Models 1000, 1010, 1020, 1021, 1023, and 1040 Portable Grooves.

There are many situations where a portable groover will be employed in a single location long enough to make a semi-permanent installation desirable. By simply adding a set of these mounting feet and bolting the machine to the floor, the user gains some increased stability and rigidity of a stationary groover. When the work is completed, the unit can quickly and easily be disassembled and trucked to a new location.

Automated Roll Groover

Model 2112 - AUTOMATED ROLL GROOVER

Specifications: Capacity: 1" through 12" pipe (25-305mm) Schedule 40

Model 2112 is a full power version of the Model 1112 and includes a self-contained hydraulic system capable of applying 15,000 psi at the point of roll grooving to handle pipe up to 12" diameter Schedule 40. The hydraulic pump, a 1-hp pump motor, and reservoir are housed in the unit's sturdy steel base. Once the Automatic Depth Stop is set, the operator depresses a footswitch, and the machine rolls the groove to the predetermined depth. Moving the Pressure Release Handle retracts the hydraulically powered Ram so the operator can remove and check the groove. Model 2112 is shipped completely assembled. MODEL 2112 SPECIFICATIONS Capacity: 1" through 12" Schedule 40 (10mm) 2" through 8" Copper Tubing K, L, M, and DWV Pipe Rotation Speed: 35 RPM Hydraulic Pressure at Roller: 15,000 psi max. Spindle Height from Floor: 35" (889mm) Electric Drive Motor: 1 1/2 HP 60Hz 110 V 1 PH Hydraulic Pump Motor: 1 HP 60 Hz 110V 1 PH Floor Space Required: 30" x 22" (762x559mm) Shipping Weight: 470 lbs. (213 kg) Interchangeable Rollers: TOP PIPE DIAMETER/ BOTTOM PIPE DIAMETER 1" through 1 1/2" (25-38mm)/ 1" through 1 1/2" (25-38mm) 2" through 6" (51-152mm)/ 2" through 6" (51-152mm) 8" through 12" (203-305mm)/ 8" through 12" (203-305mm) *Other current characteristics available. STANDARD EQUIPMENT Electric Drive Motor Limit Switch for Depth Gauging Groove Depth Gauge Hydraulic Pump Motor Hydraulic Pump Top and Bottom Rollers 1" through 12" Guards Footswitch Nipple Bracket OPTIONAL: Top and Bottom 2-8" copper tube grooving roll sets, Bottom 2-12" 10 Gauge stainless steel bottom rolls.

Portable Roll Groover

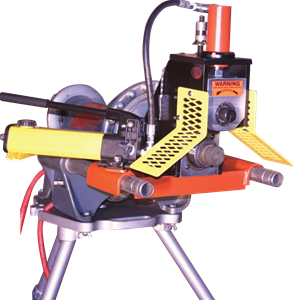

Model 1012 - 1" through 12" SCHEDULE 40 PORTABLE ROLL GROOVER

Specifications: Capacity: 1" through 12" 40 (10mm) 2" through 8" Copper Tubing K, L, M, and DWV Shipping Weight: 125 lbs.

When the ultimate is required in your grooving needs 1" through 12" Schedule 40, the PACE model 1012 will answer those needs. This PACE design -- with new hydraulic ratio along with advanced spindle design -- allows greater strength and pressure in a compact package for grooving up to 12" Schedule 40, using a standard model RIDGID(R) 300. A hydraulic hand pump will deliver increased pressure for grooving up to .406 wall pipe to specification quality grooves. Top and bottom roll changes are easy with cross taper pin in the bottom roll and socket set screw in the top roll for positive no-slip design. Like all PACE Roll Grooving tools, the model 1012 is designed for trouble-free service. Interchangeable Rollers: TOP PIPE DIAMETER/ BOTTOM PIPE DIAMETER 1" through 1 1/2" (25-38mm)/ 1" through 1 1/2" (25-38mm) 2" through 6" (51-152mm)/ 2" through 6" (51-152mm) 8" through 12" (203-305mm)/ 8" through 12" (203-305mm) STANDARD EQUIPMENT Grooved Depth Gauge Hydraulic Hand Pump Shipping/Storage Box Rollers as specified in Price List Pipe Nipple and Stabilizer Bracket Guards OPTIONAL: Top and Bottom 2-8" copper tube grooving roll sets. Bottom 2-12" 10 Gauge stainless steel bottom rolls

Model 1023 - PORTABLE ROLL GROOVER

Specifications: Capacity: 1 1/4" through 24" (32-610mm)

This Portable Pipe Groover is designed with a heavy-duty, high-efficiency gear reducer. The helical inline gear reducer with only 5% energy loss will allow pipe grooving 1 1/4" through 24" with a 110-volt electrical service. Hand hydraulic pump applies up to 16,000 psi at the point of roll grooving to produce accurate grooves for quick installation of pipe couplings. Use it at the job site or in the shop. Top and bottom rollers are interchanged easily to handle a wide range of pipe diameters. MODEL 1023 SPECIFICATIONS Capacity: 1 1/4" through 12", Schedule 40 (10mm) 12" through 24" Standard Wall .375 wall (9.5mm) 2" through 8" Copper Tubing K, L, M, and DWV Pipe Rotation Speed: 30 RPM Hydraulic Pressure at Roller: 16,000 psi max. Spindle Height from Floor: 33" (838mm) Electric Drive Motor: 1 1/2 HP 60Hz 110 V 1 PH Floor Space Required: 31 1/2” x 33 1/2” (800 x 857mm) Shipping Weight: 430 lbs.

Model 1112 - PORTABLE ROLL GROOVER

Specifications: Capacity: 1" through 12" pipe (25-305mm) Schedule 40

Model 1112 requires just 3 Top Rollers and 3 Bottom Rollers to produce specification quality grooves in a pipe from 1" through 12" diameter Schedule 40. Easily portable for on-the-job work, the Model 1112's electric motor rotates pipe at speeds of 35 RPM. The hand hydraulic pump will deliver up to 15,000 psi pressure at the point of roll grooving. Like all PACE Pipe Grooving Machines, Model 1112 is built to deliver long, trouble-free service. MODEL 1112 SPECIFICATIONS Capacity: 1" through 12" SCHD 40 (10mm) 2" through 8" Copper Tubing K, L, M, and DWV Pipe Rotation Speed: 35 RPM Hydraulic Pressure at Roller: 15,000 psi max. Spindle Height from Floor: 35" (889mm) Electric Drive Motor: 1 1/2 HP 60Hz 110 V 1 PH Floor Space Required: 32" x 32" (813x813 mm) Shipping Weight: 220 lbs. (100kg) Interchangeable Rollers: TOP PIPE DIAMETER/BOTTOM PIPE DIAMETER 1" through 1 1/2" (25-38mm)/ 1" through 1 1/2" (25-38mm) 2" through 6" (51-152mm)/ 2" through 6" (51-152mm) 8" through 12" (203-305mm)/ 8" through 12" (203-305mm) *Other current characteristics available. STANDARD EQUIPMENT Electric Drive Motor Groove Depth Gauge Hydraulic Hand Pump Top and Bottom Rollers 1-12" Shipping/Storage Box Guards Foo switch OPTIONAL: Top and Bottom 2-8" Copper Tube Grooving Roll Sets, Bottom 2-12" 10 Gauge Stainless Steel Bottom Rolls

Mini-Mites

PACE 1039 Mini-Mite(TM)

Specifications: Capacity: 1 1/4" through 6" Schedule 40 (7mm) 2" through 8" Copper Tube K, L, M, and DWV

With ratchet hand crank, roll grooves 1 1/4" to 6" Schedule 40 or thin wall steel pipe on the scaffold or anywhere power is unavailable. This service tool goes from in-place grooving and can be chucked in a RIDGID(R) Model 300 in seconds with no gearbox removal. The product is self-contained and can be operated with its own multi-function crank, so no other tools are needed. All hex drives on the 1039 are 15/16", so one wrench fits everything. Mini-Mites(TM) require no modifications or parts changes to groove any pipe or tubing in their size range. Each comes with a multistep depth gauge. STANDARD EQUIPMENT: Ratchet with 15/16" deep socket OPTIONAL: 2" through 8" Copper Roll Set